The goal of quality control is to ensure that all parts are manufactured to exact and in repeatable tolerances.

During production, we ensure to keep the prescribed quality of the parts according to the standards specified on the drawings and according to the customer’s requirements.

Adherence to standard metrology principles is a matter of course.

Our equipment is carefully cared for, and regular renewal of metrological continuity is a matter of course. In the case of customer requirements, we supply parts including measurement protocols.

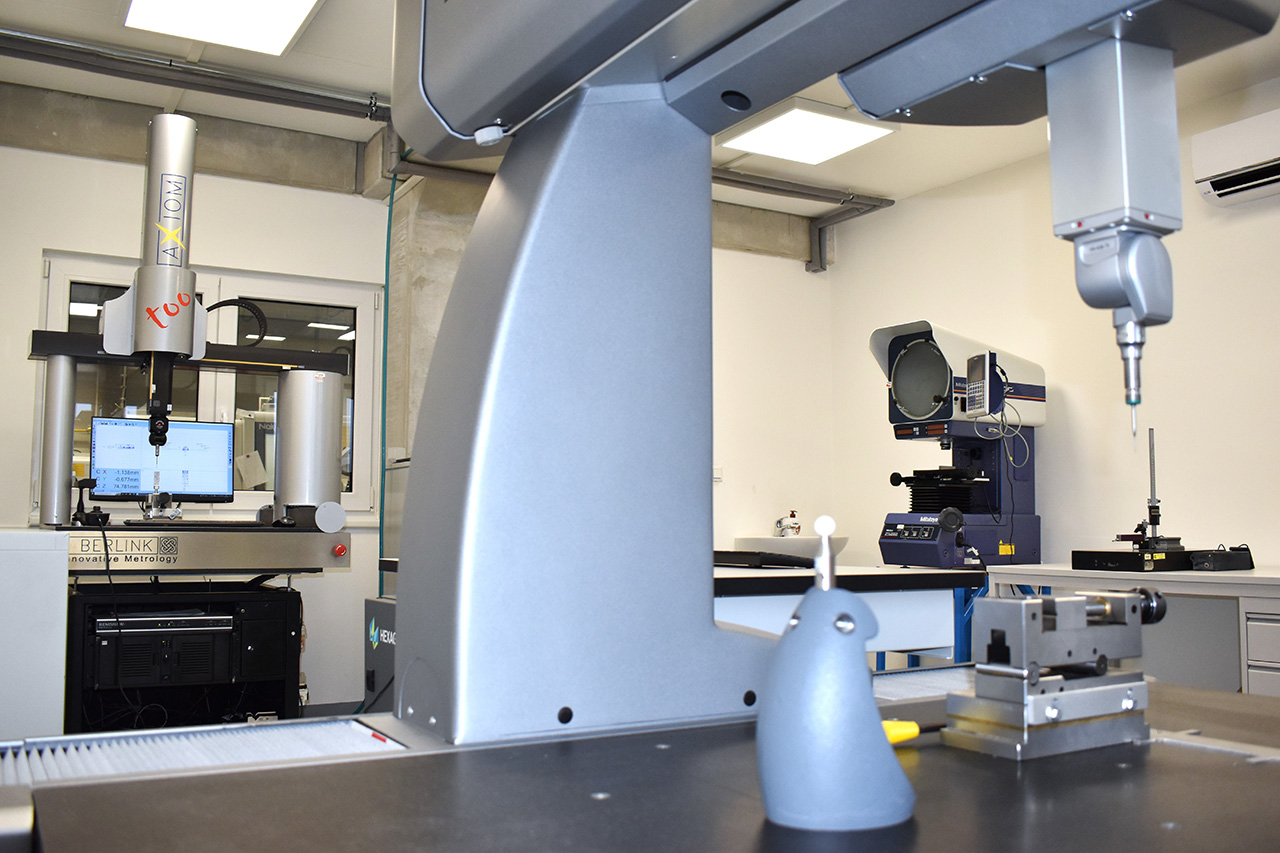

FOR DIMENSIONAL CHECK WE HAVE >>

HEXAGON GLOBAL S GREEN

ABERLINK

CNC controlled 3D coordinate measuring machines including optical cameras for measuring contours and profiles

MITUTOYO PJ-A3000

Profile projector MITUTOYO PJ-A3000 with date unit QM-DATA 200

MITUTOYO Surftest SJ-210

MITUTOYO Surftest SJ-210

roughness tester with surface roughness analysis in accordance with various international standards (EN ISO, VDA, ANSI, JIS)

Certified micrometers, calipers, end gauges, cavity gauges and height gauges